Integrated axial flow pump station

Integrated precast pump station for sewage collection and transmission in residential area or rural community and product overview of integrated pump station

GRP integrated prefabricated pump station, integrated pump station (hereinafter referred to as pump station) is an equipment to to lift sewage, rainwater, drinking water, waste water and so on. The turn-key new environmental protection and new generation pump station is designed, manufactured, assembled and shipped to the site for installation. Pump station series products have the characteristics of short construction period, easy installation, small volume, high efficiency, intelligent network and other modern products, compared with the traditional pump station, the amount of civil engineering, investment can be reduced by more than half, the product quality is reliable, is a substitute for the traditional concrete sewage lifting pump station.

Integrated prefabricated pump station, integrated pump station product overview of the scope of application

Sewage collection and transportation in residential or rural communities

Sewage collection and transportation in urban sewage treatment plants

Rainwater collection and transportation in low-lying areas of urban areas

Construction and transformation of municipal sewage network

Renovation and expansion of old pumping station

The circulation of water in a lake

Integrated prefabricated pump station, integrated pump station product overview product features

Customized: Each set of pump station is designed according to the parameters provided by the customer to ensure that the operation conditions of the pump station in order to meet the use requirements. The use of CFD fluid calculation enables as much as possible to remove silt and other solid particles from the equipment.

Industrial control design: According to user needs can use Schneider Electric, touch screen design, including communication RS485 interface. The pump station is equipped with manual control, automatic control and remote detection functions APP control. Different control modes can be freely switched.

New material: the pump station simplified structure is made of fiber winding glass fiber reinforced plastic (GRP), fully automatic control continuous winding molding, to ensure uniform thickness and reach the designed stiffness, quality stability and excellent.

Accessories standard: All accessories are designed and manufactured in the factory, including pressure pipeline, maintenance platform, inlet and outlet water pipe, etc. Strict debugging is carried out before delivery to ensure the reliability of the pump station

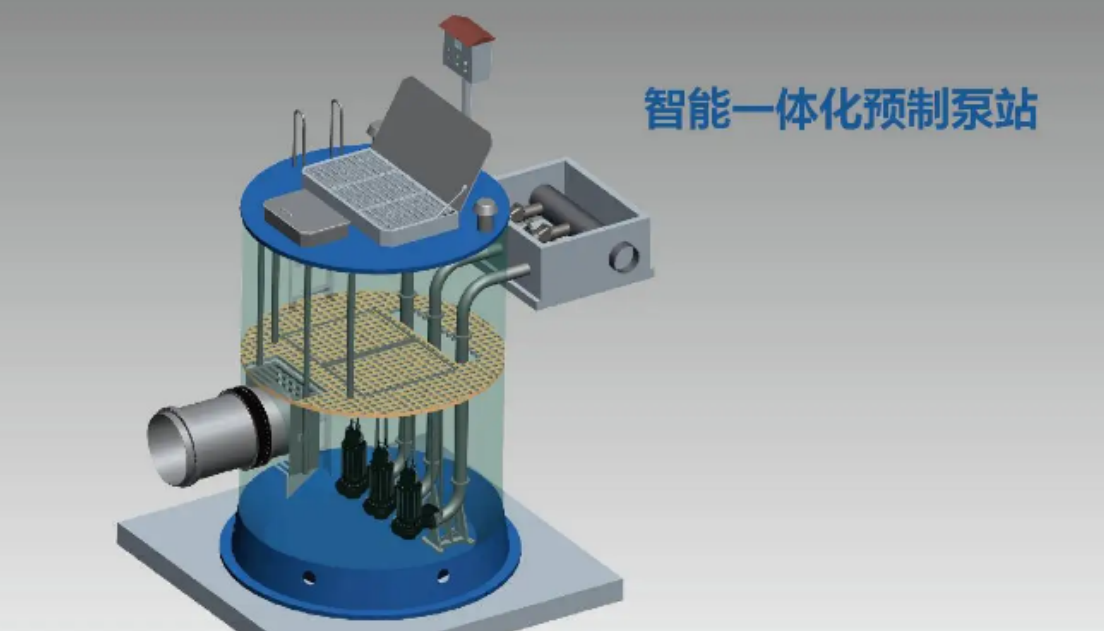

Highly integrated: Pump station as an integrated equipment, complete sets of: pump station simplified, pressure pipeline, maintenance platform, maintenance ladder, grating filter device, coupling system, pump lifting system, ventilation device, anti-slip manhole cover, lighting system, etc.

Beautiful appearance: The pump station is all buried underground, with only manhole and control box on the ground, and the landscape management room can also be selected to be placed on the ground to coordinate with the surrounding environment.

Cost saving: The pump station is a complete set of supply, and all internal installation and debugging work is completed in the factory. Only the whole installation of the pump station is required on site, which greatly reduces the construction cycle and project cost of civil engineering, and reduces the overall investment of the owner

Service life: The pump station is made of fiberglass steel, and the internal parts are made of SUS304 and hot dip galvanized anti-corrosion materials The normal service life can reach more than 30 years without maintenance.

Convenient maintenance: Water pump and basket grid are all equipped with guide rail, maintenance can be quickly removed and installed.

Function expansion: reserved communication interface, convenient customer centralized management.

----------------------------------------------------------------------

Integrated prefabricated pump station, integrated pump station product overview term definition

◎Physical prefabricated pump station: a pump station that integrates pumps, pipelines, control systems, grille filtration systems, lighting systems, maintenance platforms and ventilation systems and is prefabricated in the factory for lifting and conveying water media.

◎Top cover: consists of side cover and cover plate which can open of pump station.

◎Cylinder: The cylinder part of a prefabricated pump station.

◎Base: The part connected to the concrete bottom plate to hold the precast pump in place.

◎Basket type grate: equipped with guide rod and lifting chain, the basket type grate is automatically coupled to the water intake line.

◎Crushing grate: A grate consisting of a separate cutting machine or combining a cutting machine with a rotating grate.

◎Automatic coupling system: Quick installation system for automatic docking between the outlet port of submersible pump equipment and the outlet pipe.

◎Lighting system: to meet the need of maintenance and repair of the pump station at night or in the case of insufficient light.

◎Gravity pipe network: Generally different from pressure pipe, is to rely on fluid gravity as the power of the pipe network.

◎Pressure pipe network: pressure pipe network with the help of external forces, such as water pump, pressure tank and other equipment to drive liquid flow.

◎The ambient temperature should be -40℃ ~ 40℃

◎The relative humidity should be 25% ~ 85%, without water condensation

◎The water medium delivered by the pumping station shall meet the following requirements:

1、The temperature should be 0℃ ~20℃

2、PH is 4~10 (Excessive use should be mentioned at the time of ordering)

3、The large diameter of the particles in the transmission medium should be less than the size of the matching water pump

4、Voltage: 380V ( ±10% ), Three-phase five little system, 50Hz ( ±5% );220V( ± 10% ), single phase 50Hz ( ±5% )

5、Vibration frequency 10Hz~50Hz. The large vibration acceleration should not exceed 5m/s²

The operating place of the equipment is generally used in the absence of conductive or explosive dust (for environmental requirements, please put forward when ordering), can be configured with explosion-proof submersible pump (Exdl, ExdllAT4, ExdllBT4, ExdllCT4) or explosion-proof control cabinet, no corrosive metal or insulation damaging gas or steam.

----------------------------------------------------------------------

Overview of operation principle of integrated prefabricated pump station and products of integrated pump station

The pump station of gravity pipe network should adopt automatic liquid level control; Pump station drainage after lifting the medium relying on fluid gravity as power transmission network pump station should adopt automatic liquid level control, most of the current situation is this kind of control. That is, when the water level gradually rises, the liquid level float also rises with the rise of the water level. When the water level rises to the set high water level (start the pump), a water pump starts to run. Then the water level drops. When the water level stops to the low water level (stop the pump), the water pump stops running and the operation is repeated alternately. At this time, if the water level does not fall but rises, when it reaches (ultra-high water level), the two pumps will run at the same time. When the water level drops to the low water level (stop pumping), the two pumps will stop, and the above process will be repeated when the water level rises.

Integrated prefabricated pump station, integrated pump station product overview equipment control

◎Hardware: The pump station adopts programmable controller PLC combined with the touch screen with excellent performance, combined with multiple pumps flexible combination of automatic drainage lifting pump station, according to the detection of water level to automatically adjust the operation of single pump or multiple pumps to meet the needs of drainage, the whole system is always in the state of high efficiency and energy saving. The control system program adopts modular design.

◎Controller (optional) : with very high cost performance, can give full play to its powerful function in small automation system, can expand the digital quantity and simulation of the module, can connect the touch screen, responsible for handling all the system logic switching and operation, fault display and automatic operation,

◎BA interface (optional) : The standard signals provided by the pump station control system include all pump operation signals, fault signals, manual/automatic signals (all dry contacts) and level signal outputs (4~20mA). The system provides standard total start/stop signals (24VDC or 24VAC relays & GT).

◎Software: The standard 4~20mA signal is transmitted through the sensor, which can realize the automatic control of the each pump.

◎Three working modes: Manual-Stop-Automatic: Each water pump has three working modes: manual-stop-automatic. Each water pump can be started manually, but the water pump will not run when stopped

----------------------------------------------------------------------

Integrated prefabricated pump station, integrated pump station product overview performance parameter description

◎The pump head used by the pump station is not conventional according to customer requirements.

◎The number of pumps used in the pumping station is determined according to the actual demand. There is no conventional supporting system, and single or multiple pumps can be used simultaneously or in rotation.

◎The diameter and height of the pump station are not the key, but the effective volume of the pump station, which can be modified according to the actual needs of the customer.

◎According to the national drainage pumping station design requirements of comprehensive consideration, the effective volume calculation. The effective volume between pump start and pump stop liquid level should be determined according to the number of starts and stops 6~7 times per hour. The starting water level needs to consider the operating conditions of the pump. Therefore, the effective volume of the pump station is only related to the number of start and stop of the supporting pump and the design flow of the pump station. The effective volume shall not be less than the flow of a single pump in 5 minutes, as long as it meets the formula, which is also the difference between the integrated pump station and the traditional pump station, the effective volume is small, reduce investment.

----------------------------------------------------------------------

Integrated prefabricated pump station, integrated pump station product overview perfect automatic control system

In addition to the functions of self-detection, self-control and self-protection necessary for outdoor or field work environment, the integrated prefabricated pump station also has intelligent functions such as data remote transmission, automatic storage, automatic alarm, manual intervention, log recording, historical data query, remote login and hierarchical management.

Through various sensors installed in the internal of pump and pump station to transmit signals to the data acquisition and control module, data acquisition control module to filter out comprehensive judgment, after take out the useful signal interference signal of water pump control instruction, at the same time, the collected data through the GPRS module to wireless data flow on the way to the remote server. After receiving the data from the pump station, the remote server classifies and stores the data. Authorized users can log into the server through the client anywhere to consult the real-time and historical data of the sensor, and can forcibly intervene the operation of the pump station according to the actual situation. The system reserves automatic alarm setting options, through wired or wireless signals to the specific personnel's computer or mobile terminal alarm.