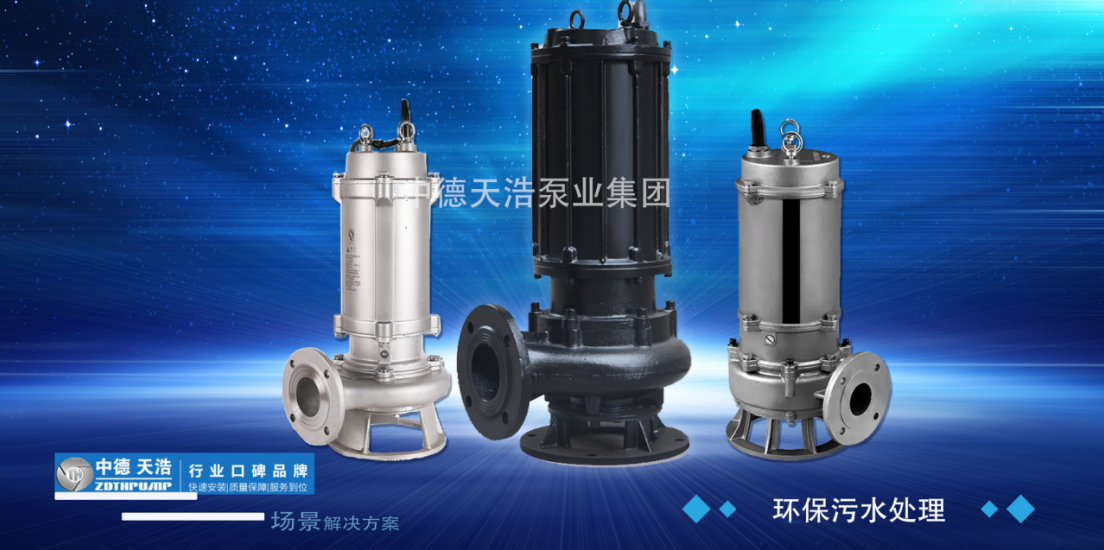

Environmental protection sewage treatment

Intelligent self-decontamination integrated pump station is used for the lifting of

sewage, rainwater, drinking water and waste water. It is a turnkey operation which is

produced and assembled by the factory and shipped to the site for installation.

The pump station consists of sewage pump, pump pit self-decontamination device, prefabricated pipe system, control system, lifting device, etc. It has the characteristics of small volume can be customized processing, new materials, good flow, low cost, high integration, simple installation and maintenance.

The pump station with super non - clogging and anti - winding ability can dispense with the grid system, and any dirt can be discharged as long as it can go in. Equipped with self-decontamination device not only can automatically clean up the dirt and floating matter accumulated in the pump pit, but also when the inlet water level is less and the liquid level is maintained at a low level, the sewage pump and automatic decontamination device can adjust the flow rate by themselves, without frequency conversion control, remote monitoring and control system is convenient for users to carry out real-time monitoring and management of the pump station.

Product usage

1、Villas, residential areas, URBAN AREAS, hilly areas, industrial parks, new rural construction, groundwater rich areas and stations, airports, schools, hotels and other facilities

2、Library, gymnasium, club training ground, etc

3、Sewage collection and transportation in garden green area, wetland protection area and other areas

4、Sewage collection and treatment of agriculture, forestry and animal husbandry plants

5、Anti-explosion zone of chemical plant

6、Rainwater collection

7、Pump station upgrade

The integrated pump station is mainly installed in the outdoor underground, but can also be used in indoor situations

Product Feather

1、Strong and beautiful

The main structure of the equipment is made of fiber wound fiberglass reinforced plastic, whose strength is double times of the traditional laminated fiberglass. It can resist tearing, corrosion and other destructive forces, so it is strong, durable and durable. The buried structure makes it integrated with the surrounding environment, beautiful and generous.

2、Short engineering cycle

The factory is responsible for the installation and debugging of each component. After the goods arrive at the site, the installation and debugging time is greatly shortened compared with the traditional pump station. The civil construction workload is 1/10 of the traditional concrete pump station, and the whole project cycle is greatly shortened.

Using small diameter pipeline layout, the laying speed of 3~4 kilometers per day, the domestic sewage will go into the nearest sewage network or directly transported to the sewage treatment plant.

3、Efficient environmental protection, cost saving

The self-equipped control operation system ensures that the water pump can run automatically according to the amount of water supplied, and the internal flow is good. The system can be self-clean without precipitation, sealed without odor, and meet the requirements of environmental protection. This series of precast pump station saves 20%~30% of the cost compared with the traditional concrete pump station, and occupies a small area, does not damage the existing above ground or underground building foundation, does not damage the environment, does not affect the residents' travel during the whole installation process of the pump station.

4、Full automatic control

The matched submersible pump uses the liquid level floating ball to automatically control the start and stop, so the whole pump station runs automatically without special personnel on duty.

5、

As an integrated unit, it provides prefabricated cylinder, submersible sewage pump, pipeline system, crushing grate, control system, lifting device, exhaust device and other parts, with large capacity and safe fixed protection to ensure the match of various parts, can meet the quality requirements of users.

6、Interception device

The interception device is installed between the water inlet and the crushing grate, which intercepts the floating objects in the sewage pipe to the crushing grate knife cavity, so that it can be effectively broken.

7、Easy installation and maintenance

Instead of entering the cylinder body, the pump and grille can be lifted in or out from the top

8、Long service life

The self-purifying thin shell cylinder base and smooth inner wall guarantee using and no maintenance. Pumps, grilles and pipes are made of anti-corrosive materials to prolong the service life.