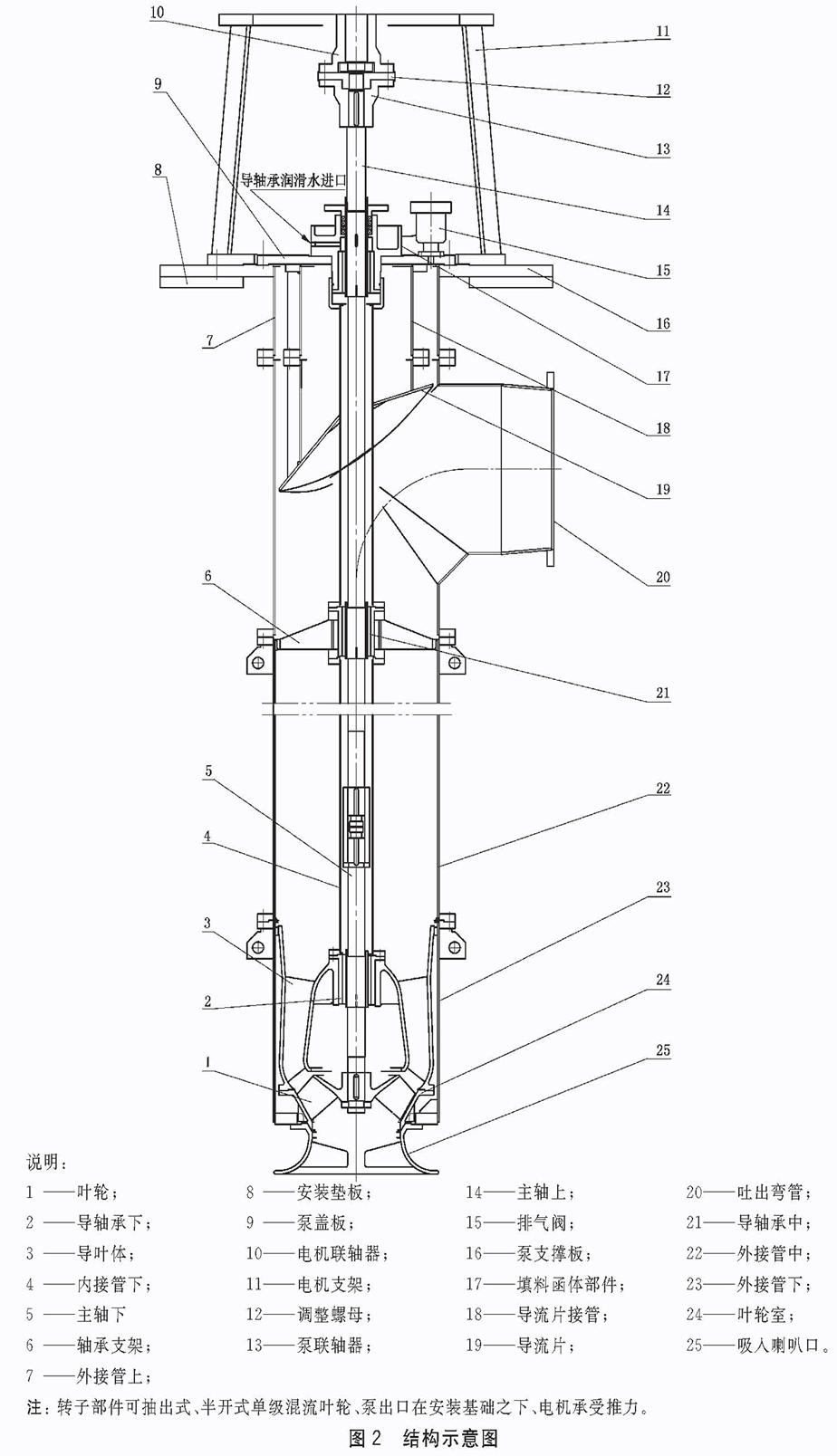

LC type vertical long shaft pump with inlet vertically downwards and outlet horizontally, single foundation installation, pump and motor directly connected; Looking down from the motor end, the pump rotates counterclockwise, with the main characteristics of:

1. By using hydraulic design software to optimize the design, the performance is superior, and the wear resistance of the impeller and guide vanes is fully considered, greatly improving the service life of vulnerable parts such as the impeller; The product runs smoothly, is safe and reliable, and is efficient and energy-saving.

2. The inlet of the water pump is equipped with a filter screen with appropriate opening size, which effectively prevents particle impurities from entering the pump and damaging the water pump. At the same time, it minimizes inlet loss and improves the efficiency of the water pump.

3. The impeller adopts a balance hole to balance axial force, and the front and rear cover plates of the impeller are equipped with replaceable sealing rings to protect the impeller and pump body.

4. The intermediate shaft, lifting pipe, and protective pipe of the pump are multiple sections, and the intermediate shaft adopts sleeve coupling technology. The number of lifting pipes can be increased or decreased according to user needs, adapting to different underwater depths. The impeller and guide vane body are multi-stage, suitable for different head requirements.

5. The water pump discharge pipe is connected by a flange and has a guide bearing in the middle. Using nitrile rubber (for medium temperatures above 55 ℃). The shaft is protected by a protective tube, and when transporting sewage, the guide bearing must be externally connected with cooling and lubricating water.

6. The residual axial force of the pump and the weight of the rotor components are borne by the thrust bearing inside the motor seat or by the motor with thrust bearing. The thrust bearing is lubricated with thin oil and cooled with external water. The thrust bearing can be embedded with temperature control components.

7. The shaft seal of the pump is a packing seal, and replaceable shaft sleeves are installed at the shaft seal and guide bearing to protect the shaft. The axial position is adjusted by the adjusting nuts on the upper end of the bearing components or inside the pump coupling, which is very convenient.

8. The water pump can be equipped with a control cabinet, which has various functions such as automatic start/stop based on liquid level, overload alarm, and real-time remote monitoring, and can achieve remote centralized control of multiple pump networks. The pump with a diameter of 500mm is equipped with an automatic exhaust system.